SUSTAINABLE MOBILITY

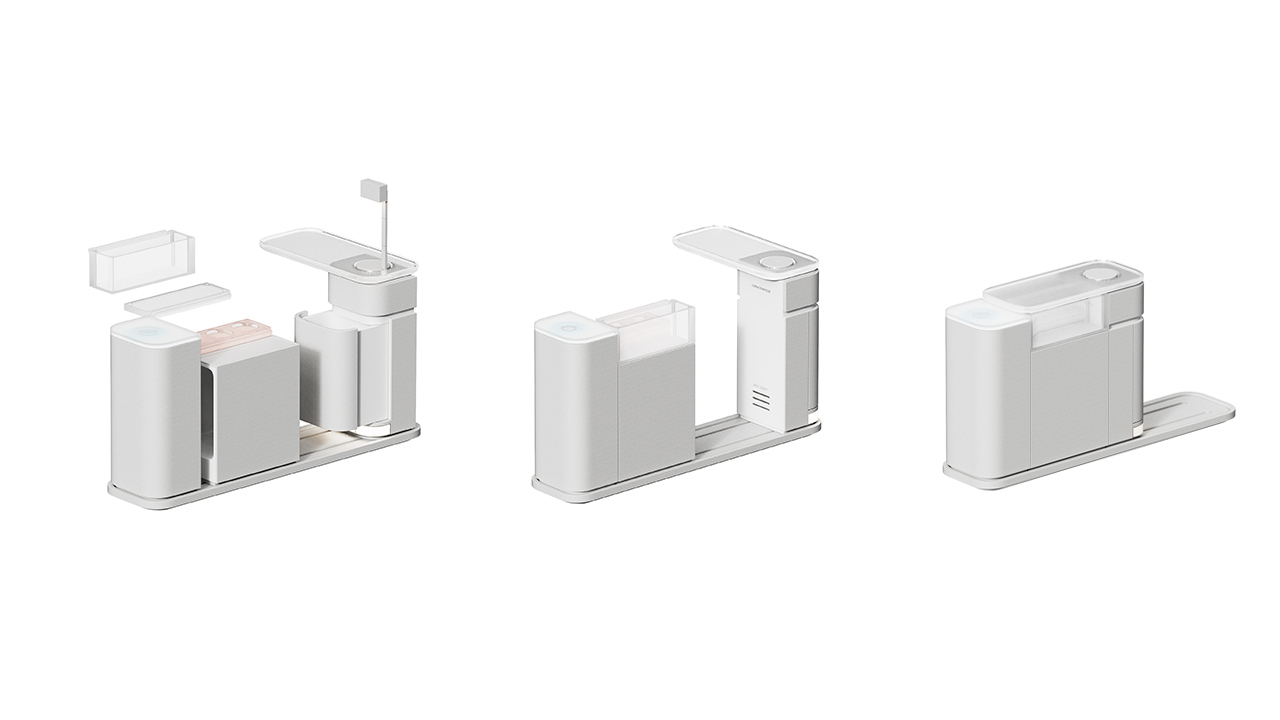

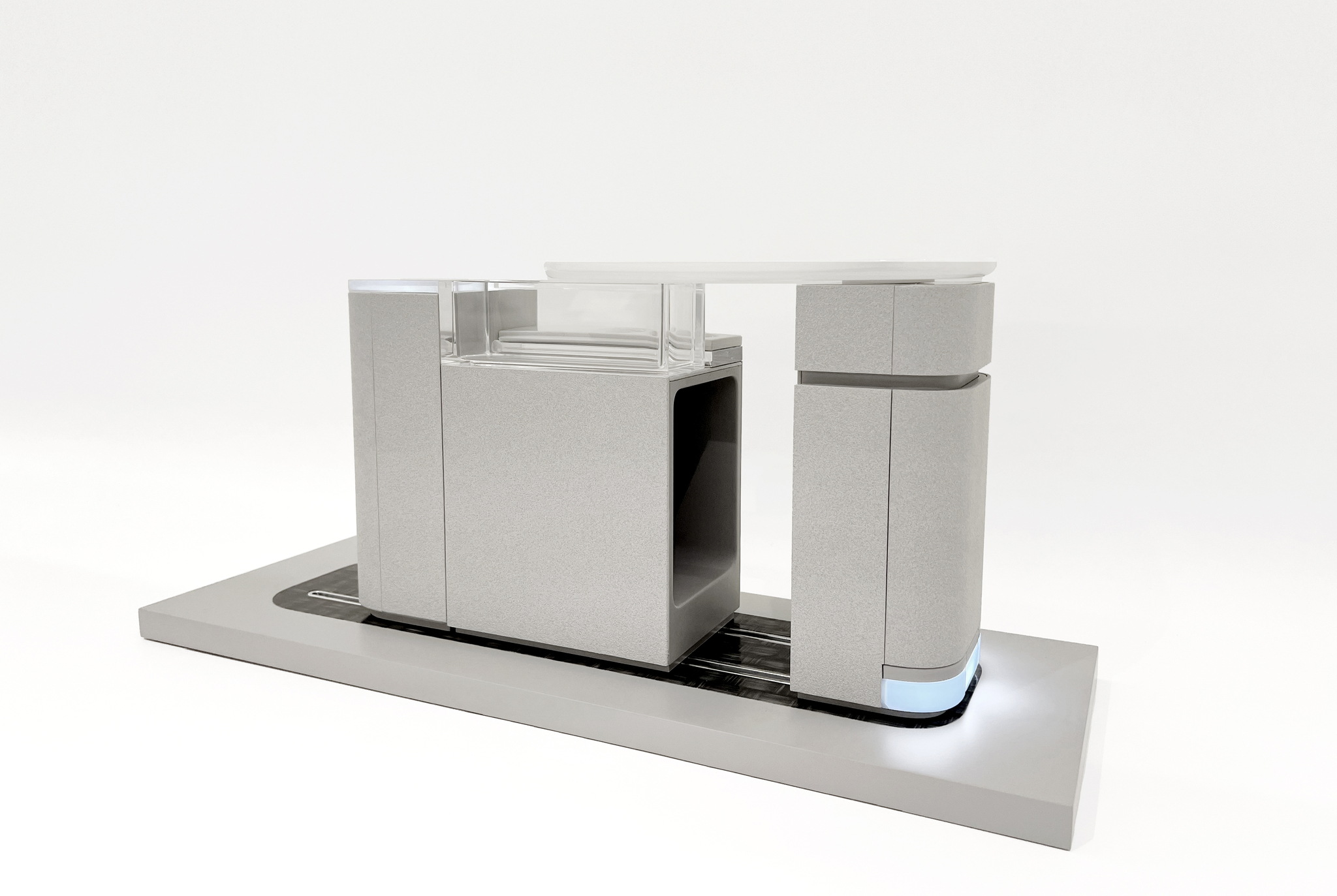

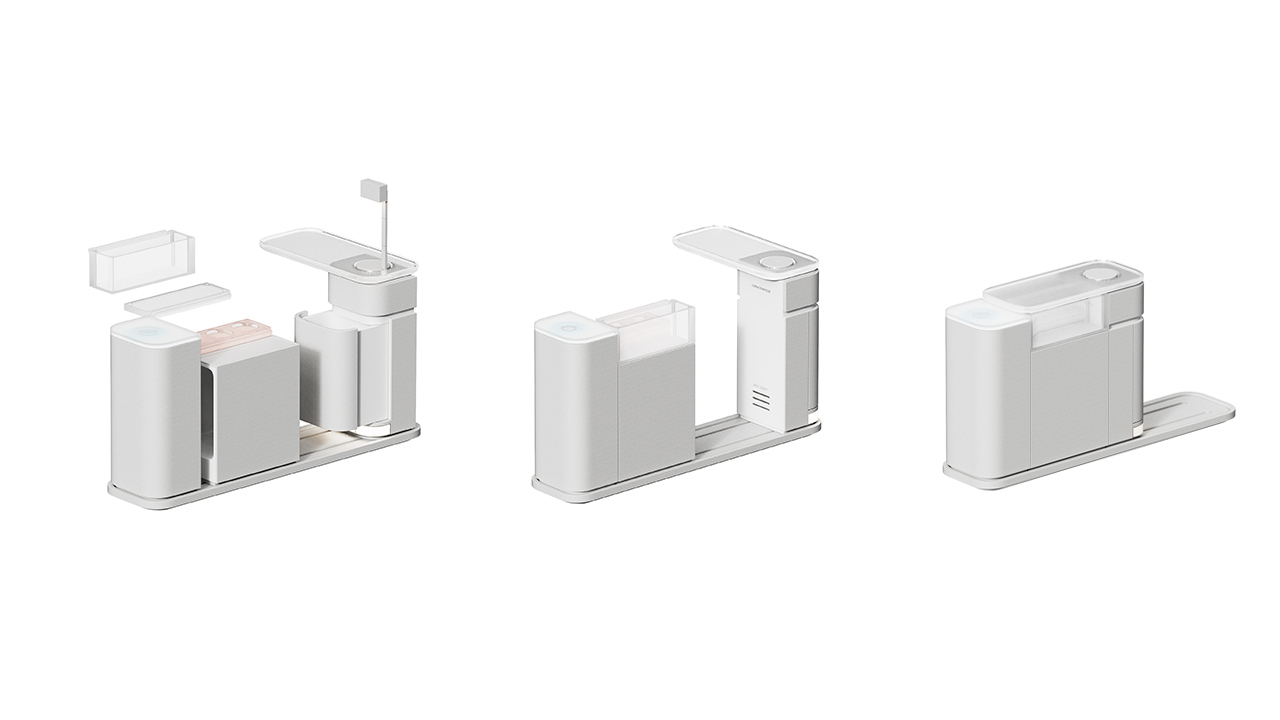

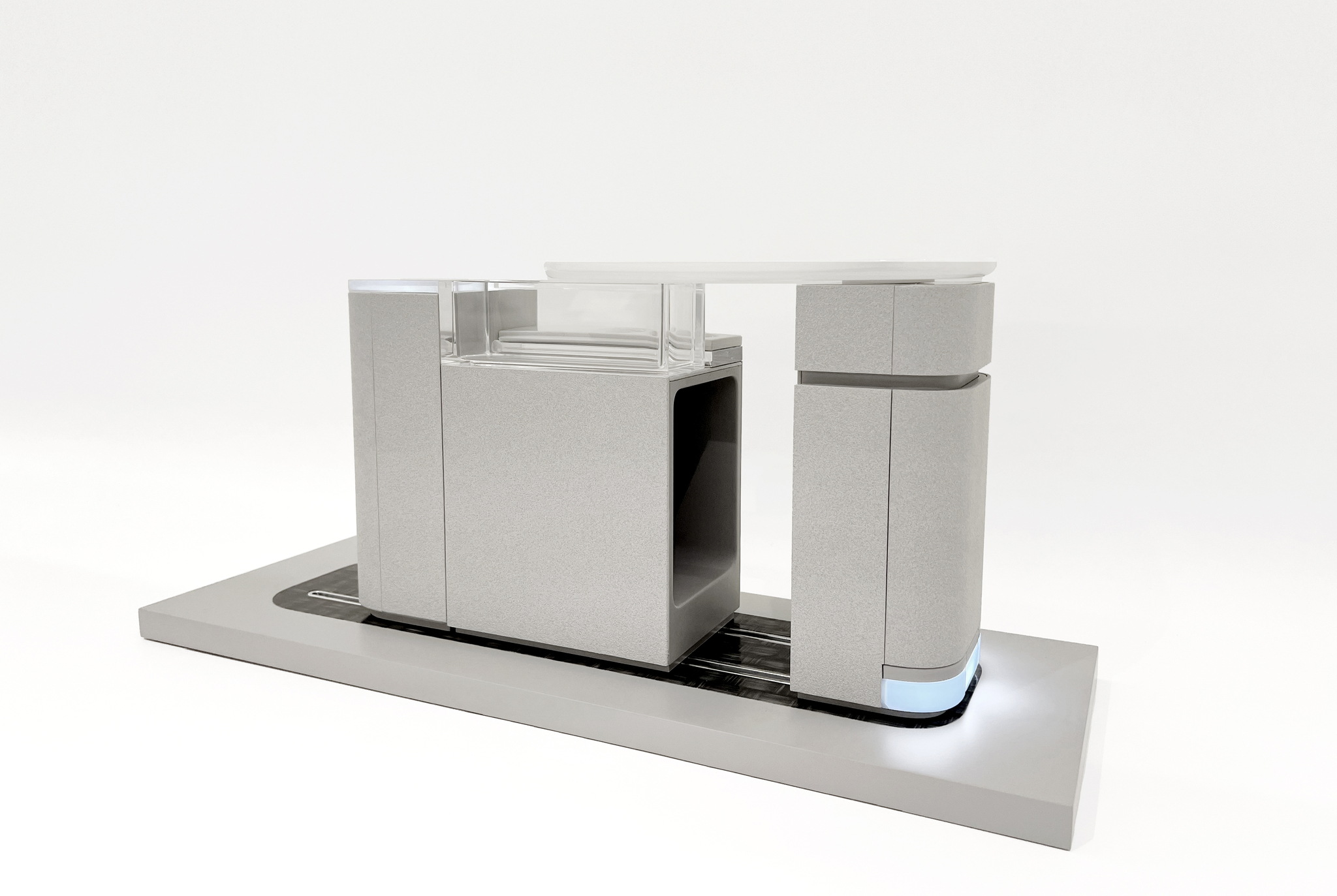

Modular Console for Future Mobility

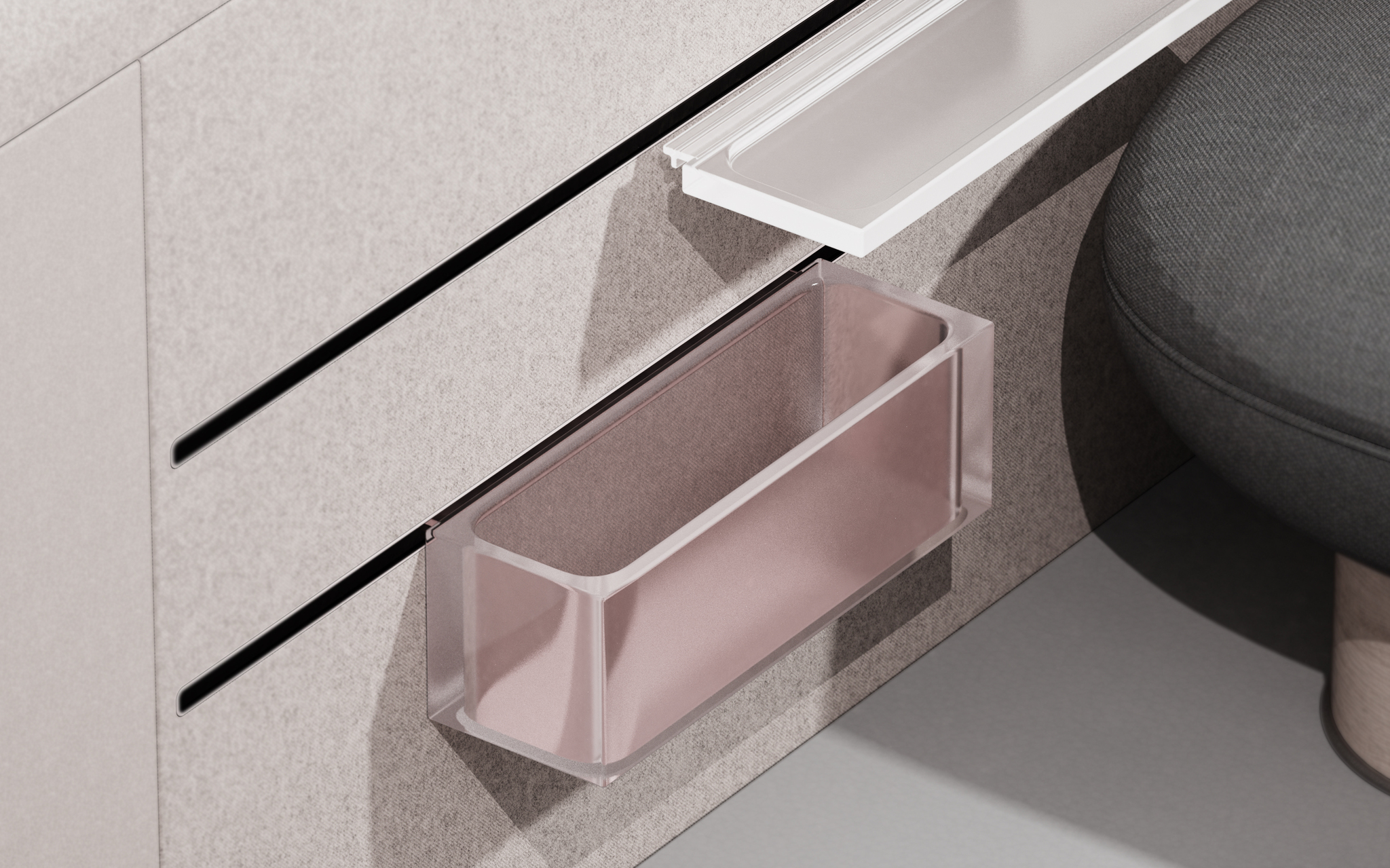

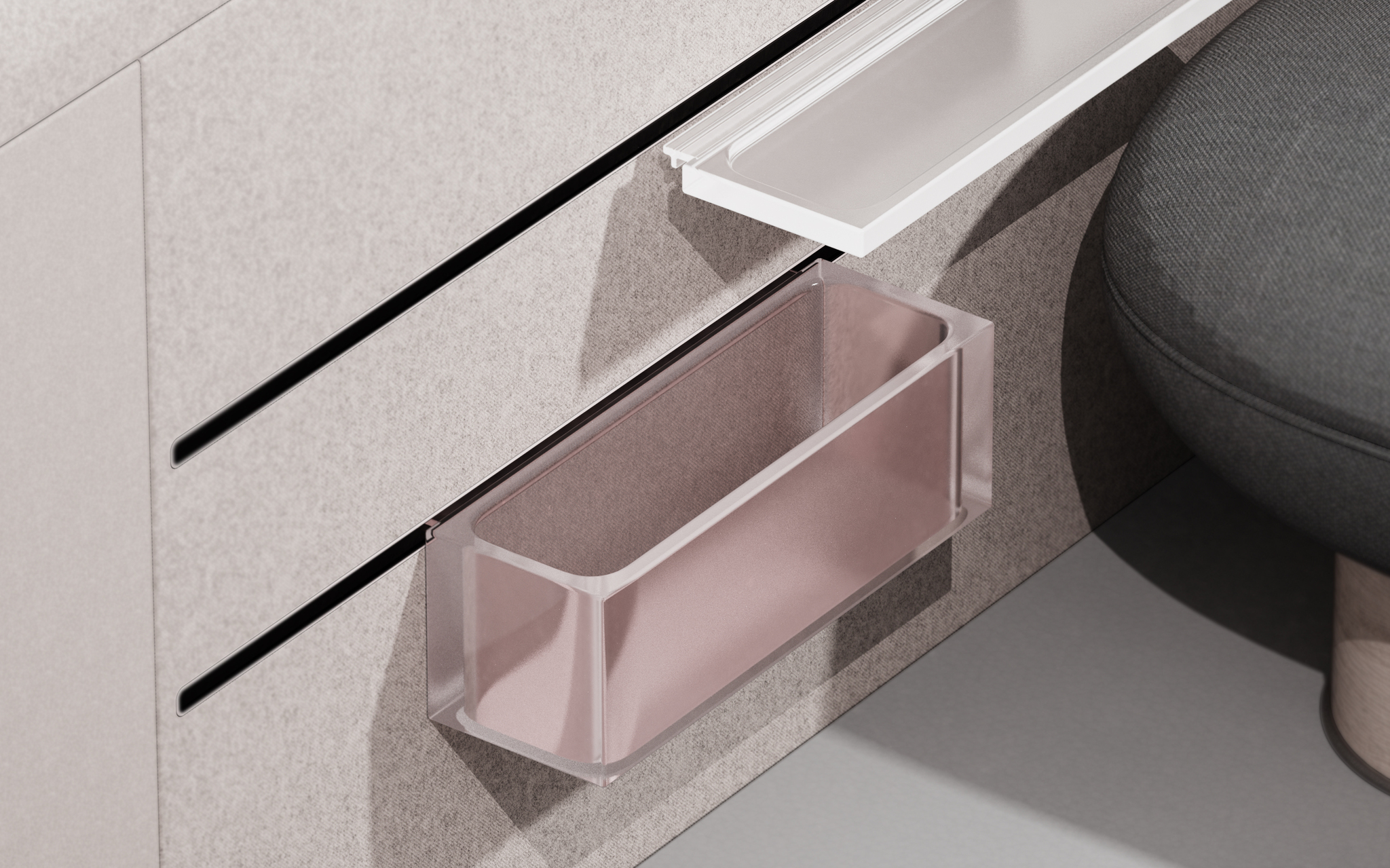

LOTTE Chemical Corp.SUSTAINABLE MOBILITY is more than just interior design. It includes ways to make customization easy, make the best use of space, and keep the hygiene—the issues that must be dealt with by shared or purpose-built vehicles in the age of autonomous driving. This solution includes choosing materials and structures suitable for mass-production. Since eco-friendly mobility interior design uses a lot of different materials, the recycling rate drops due to disposal or replacement. This problem was solved by using a mono-material solution that involved injecting the same materials twice and simplifying the joint process by using pattern forms.

Client / Manufacturer Design

Design

LOTTE Chemical Corp.

Uiwang-si, Gyeonggi-do, KR

LOTTE Chemical Corp.

Uiwang-si, Gyeonggi-do, KRmyung ok seo, soohyun chaefound / Founded

Seoul, KRDate of Launch

unknown

Development Time

up to 6 Month

Target Regions

Africa, Asia, Australia / Oceania, Europe, North America, South America

Target Groups

Consumers / Users