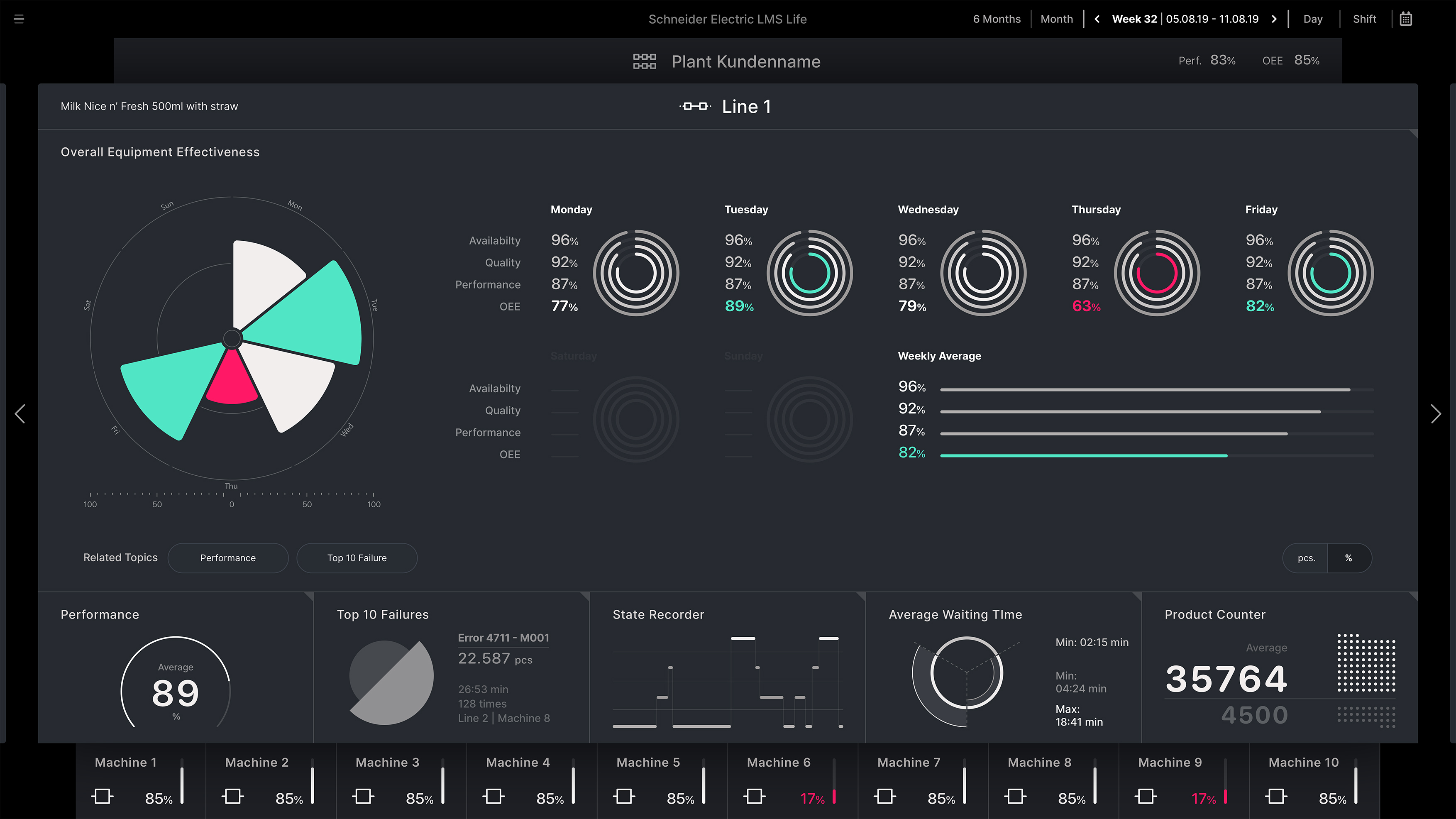

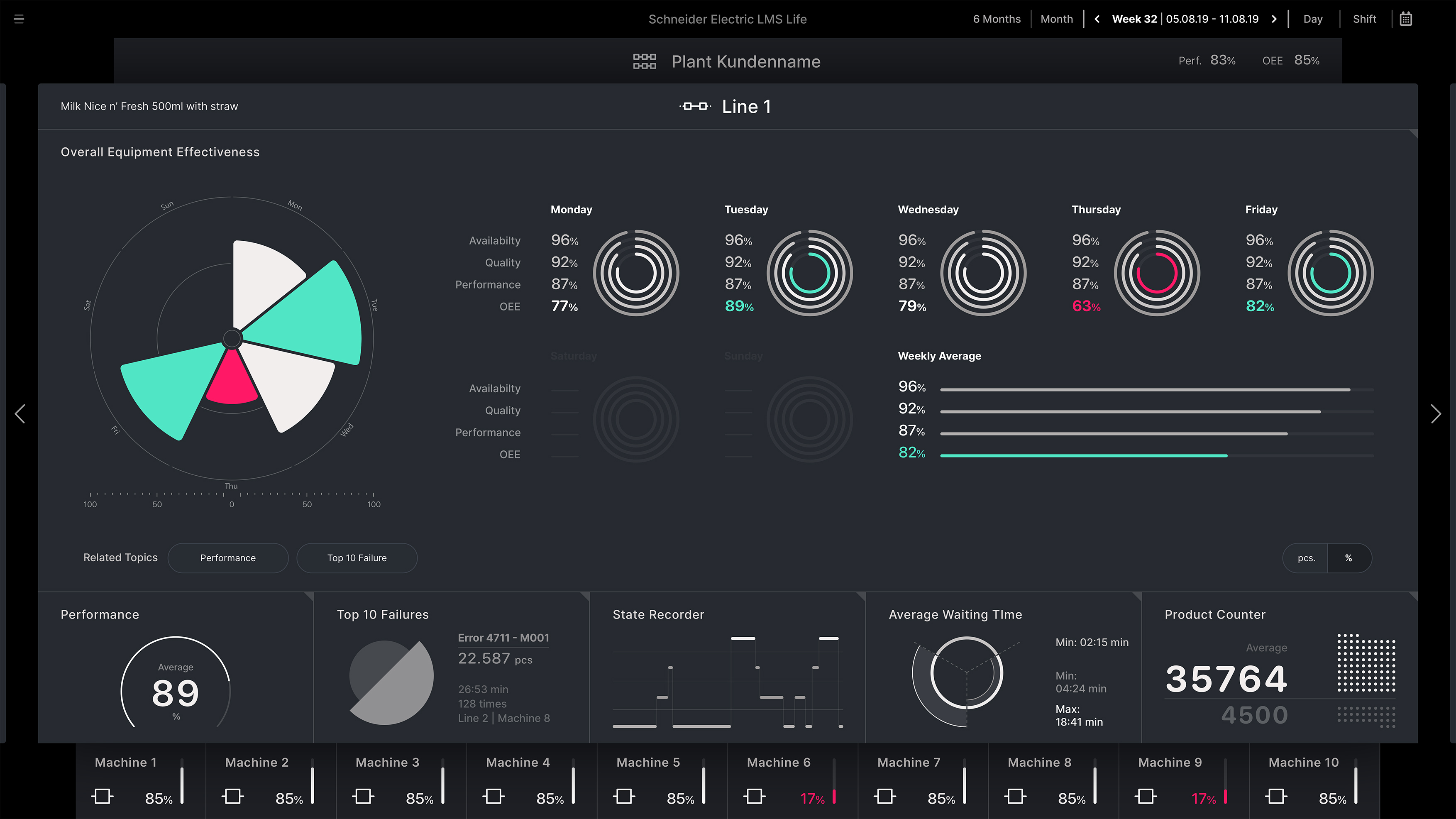

LMS LIFE – Next Generation Line Monitoring System

Manufacturing control software UI

Schneider Electric Automation GmbHThis user interface was created for software used in manufacturing IoT to monitor the performance and efficiency of production machines. The collected data is presented in easy-to-understand infographics so that the user can quickly recognize potentials for reducing errors and optimizing production. A simple drill-down principle allows the user to switch from the plant level via the line level to the machine level and identify any anomalies. Smart filter and comparison functions provide additional support. Well-designed information graphics were specifically adapted to the software's specific topics and information content.

Client / Manufacturer Design

Design

Schneider Electric Automation GmbH

Marktheidenfeld, DE

HMI Project GmbH

Würzburg, DEDate of Launch

2020

Development Time

13 - 24 months

Target Regions

Asia, Europe, North America

Target Groups

Trade / Industry